cold cutting

FUTURE INDUSTRIAL SERVICES

hydro abrasive cutting equipment

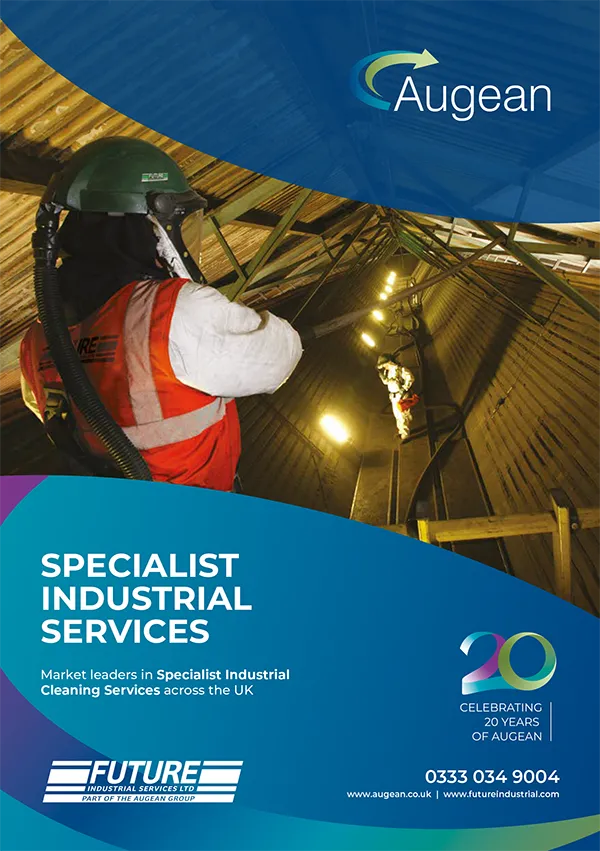

FIS is a leading provider of cutting-edge hydro abrasive cutting technology that is revolutionising industrial processes across a wide range of critical sectors.

Unlike other hydro abrasive cutting systems, that require ultra-high pressures, the FIS system achieves the same performance levels at a much lower, safer, and more efficient pressure of 5,500 psi.

With their state-of-the-art equipment and highly skilled, experienced operators, FIS delivers unparalleled precision and efficiency in applications ranging from petrochemical refinement to chemical manufacturing to natural gas extraction and beyond.

Their advanced hydro abrasive cutting systems utilise powerful streams of water mixed with abrasive particles to slice through even the toughest industrial materials with remarkable accuracy, making them an invaluable asset for companies in the petro-chemical, chemical, gas, and utilities industries who require clean, controlled cuts for component fabrication, maintenance, and repair.

HOW TO...

MINIMISE YOUR ENVIRONMENTAL IMPACT

Our systems are commonly used on :

- Cutting doorways, floors, and removing roof sections from storage tanks

- Decommissioning and removing sections of pipework

- Cutting openings into refractory-lined units

- Cutting through columns and vessels

Hydro abrasive cutting is :

- A versatile technology that offers several key benefits

- It is spark and heat-free, making it suitable for cutting steel, specialist alloys, concrete, and thermally-lined pipework, including vessels and steel composites

- The system is zone 2 rated and self-supported, ensuring it can be safely used in explosive atmospheres

FIND OUT MORE

OUR PROCESS:

FIS cutting system can perform precise, burr-free cuts on extremely thick and hard materials without creating a heat-affected zone. This is achieved through a specialized weld preparation process that minimizes impact on the underlying material.

- Each cutting unit operates continuously, powered by twin pressure cylinders that generate the necessary hydraulic pressure and flow to handle a wide range of cutting shapes and angles.

- The cutting head can operate up to 500 meters away from the main unit and has been used for cuts at heights up to 100 meters, as well as underwater applications.

- Unlike other hydro abrasive cutting systems that require ultra-high pressures, the Future system achieves the same performance levels at a much lower, safer, and more efficient pressure of 5,500 psi. This is made possible by the company's proprietary direct injection technology.

expert care

Why Choose Future Industrial Services?

The versatility of FIS’ technology extends beyond commercial applications – their equipment is also relied upon for specialised military and defence projects where the ability to make intricate cuts in armoured materials or hard-to-reach areas is of the utmost importance.

Leveraging decades of engineering expertise, FIS continues to push the boundaries of what’s possible with hydro abrasive cutting, delivering innovative solutions that help their clients operate more efficiently, cost-effectively, and safely across a diverse array of mission-critical industrial and defence initiatives.

let's work together

FIS offers a proven track record of delivering expert, efficient cold cutting solutions tailored to meet our clients’ needs. As a trusted partner committed to innovation and sustainability, we invite you to contact us today to discuss a customised solution for your requirements.